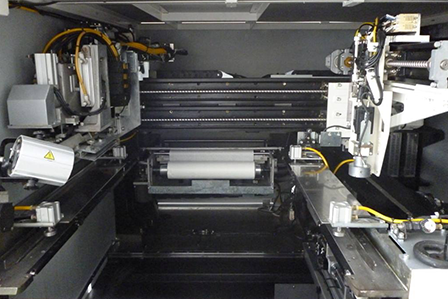

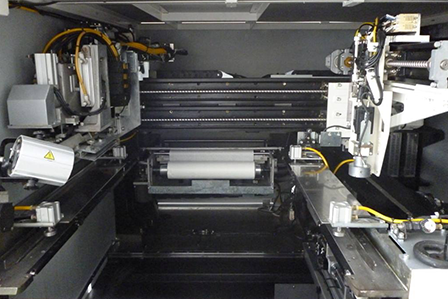

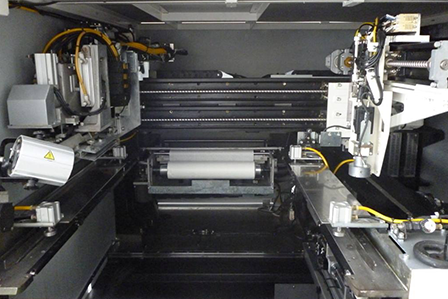

Mounter arch type

The component feeder the substrate (PCB) are fixed. The placement head (with multiple vacuum suction nozzles) is moved back forth between the feeder the substrate. The component is removed the feeder, the component position direction are adjusted. Place on the substrate. The chip head is named because it is mounted on an arched X / Y coordinate moving beam.

The method of adjusting the position direction of the components by the arch mounter:

1). Mechanical centering adjustment position nozzle rotation adjustment direction. This method can only achieve limited accuracy, the later models are no longer used.

2). Laser recognition, X / Y coordinate system adjustment position, nozzle rotation adjustment direction. This method can realize recognition during flight, but it cannot be used for ball grid array element BGA.

3). Camera recognition, X / Y coordinate system adjustment position, nozzle rotation adjustment direction. Generally, the camera is fixed, the chip head flies over the camera for imaging recognition. It takes a bit longer than laser recognition, but it can identify any component. The camera recognition system that realizes recognition during flight has other sacrifices in terms of mechanical structure.

In this form, the speed of the patch head is limited because it moves a long distance back forth. Generally, multiple vacuum suction nozzles are used to take materials at the same time (up to ten) a double beam system is used to increase the speed. , Almost twice as fast as the single beam system. However, in practical applications, the conditions of simultaneous feeding are difficult to achieve, different types of components need to be replaced with different vacuum suction nozzles, there is a time delay in changing the suction nozzles.

The advantage of this type of machine is that the system has a simple structure can achieve high precision. It is suitable for components of various sizes shapes, even special-shaped components. It is suitable for small medium batch production, multiple machines can be combined for large batch production.

13962439646

Address: No. 259 Songjiagang Road, Zhoushi Town, Kunshan City, Suzhou City, Jiangsu Province

Email: srd@kunshansmt.cn