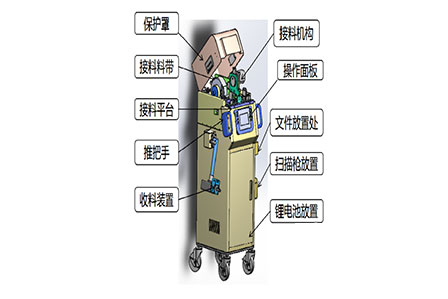

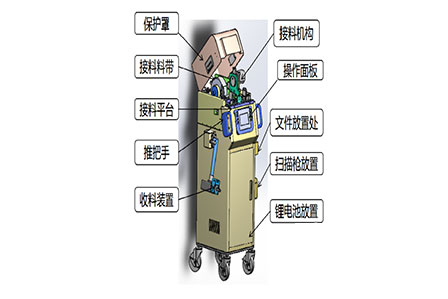

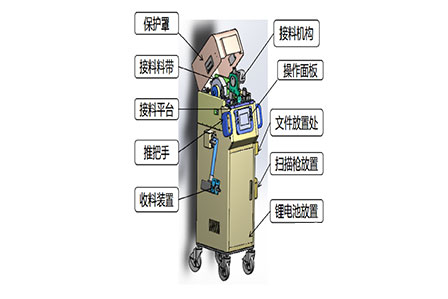

Introduction of automatic feeder device

Brand: Senruida Intelligent Place of Origin: Jiangsu, China

Provincial personnel: improve operation efficiency success rate of receiving materials, reduce production line personnel by more than 30%;

Anti-mismatch (6 seconds principle, optional function)

The equipment can be directly connected to the MES system, it can use its own independent material comparison system. The time difference between the confirmation signal of the new material tray connected with the receiving device the confirmation signal sent by the MES system to the correct information of the new old material tray should be controlled within 6 seconds. Once the employee finds that the scan fails, if the new tray is replaced without permission, the time will be more than 6 seconds, the device will alarm. Intervention by higher management.

Once the tray is hung on the tray, it cannot be removed before the old new materials are connected. If the material on the hanging device is found to be incorrect removed replaced, the system issues an alarm! Intervention by higher management. Reduction of poor material intake caused by human factors, especially new employees' poor materials, leading to production line downtime.

The equipment operation rate is increased by more than 6%, the bulk material can be continuously docked, which greatly improves the operation quality the probability of passing, which can be more than 98% (the probability of passing by about 50%)

Power supply: AC110V / 220V 50 / 60Hz 50W (equipped with UPS backup power)

Air pressure requirement: above 0.45Mpa; clean dry

13962439646

Address: No.333 Youbi Road, Zhoushi Town, Kunshan City, Suzhou City

Email: srd@kunshansmt.cn